Inflatable Seals

Inflatable Seals

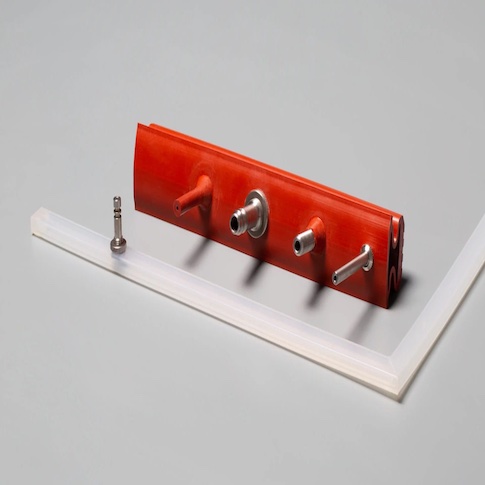

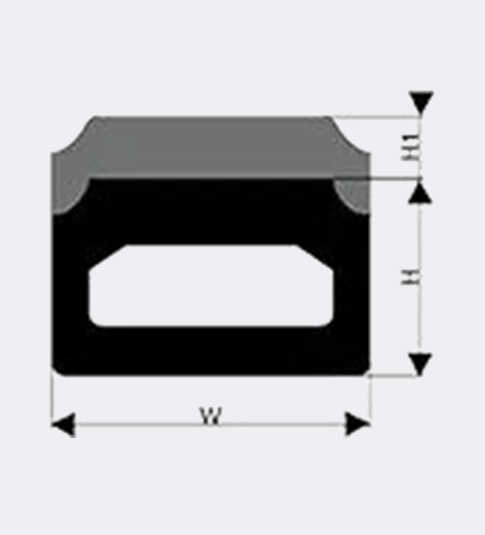

American Rubber Corp is a leading supplier and manufacturer of Inflatable rubber seals with customizable valve & inlet tube. We provide design consultation and material selection help to our customers including important parameters around inflation height and deflation (relaxed state) gap, as well as pressure, and operating temperature requirements.

Inflatable seals are a type of rubber seal that inflates to provide a contamination-proof seal in a variety of applications. Unlike traditional elastomeric seals, inflatable seals can effectively seal irregular or misaligned surfaces, enhancing their sealing integrity. Their unique design allows them to inflate and form a tight barrier between the mounting and striking surface. Inflatable seals are easy to use, requiring less force while ensuring a 100% seal. They are the perfect solution for unique sealing applications.

- Non-Reinforced Inflatable Seals

- Fabric Reinforced Inflatable Seals

- Custom & Standard Inflatable Seals

Product Description:

Across industries inflatable seals are called different names like pneumatic gaskets or dynamic seals. American Rubber Corp has capability to custom design and manufacture inflatable rubber seals of various profiles either extruded and joined for endless gasket or full mold them in continuous molding and mandrel operations. Inflatable seal geometry, operating conditions, desired pressure, and the method and interface the seal will be installed on are some of most critical aspect of achiving desired sealing quality as well as operating life longetive from these inflatable seals.

We manufacture custom designed reinforced inflatable gaskets

depending on requirements and specifications or operating application details provided by our customers. Reinforcement material that we add to inflatable seal depends on desired operating pressure and temperature. We provide choice of polyester, cotton, nylon, nomax, and kevlar reinforcement for our custom manufactured inflatable seals.

Futhermore, our inflatable seals are manufactured for radially inward as well as radially outward sealing depending on application requirements.

ARC’s dedicated team is always ready to provide advice and recommendations on inflatable seal materials and design. They work closely with you from the initial design stage all the way through to the final manufacturing run, ensuring that you receive the best possible gaskets for your needs.

Type of Inflatable Seals We Manufacture

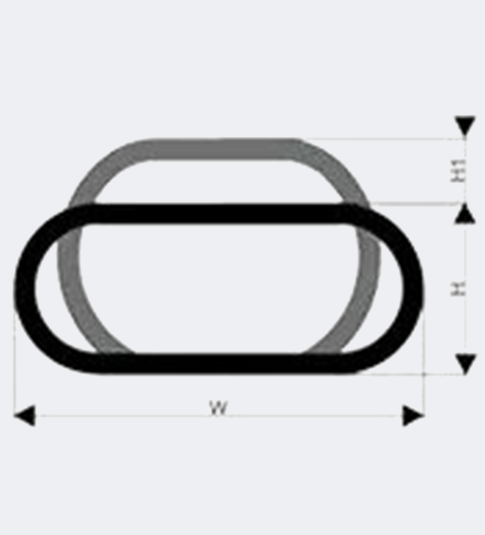

| Footless SealsFoot less inflatable seals are made without any special geometric features at the bottom of the seals. These types of inflatable seals are installed with either PSA backing or in pre-machined grooves and usually towards lower half of horizontal matting mating surface. Simpler design allows for economical cost of such seals while providing all other benefits of inflatable seals. In certain cases, footless inflatable seals are secured through pressure plate and fasteners if required by application. |

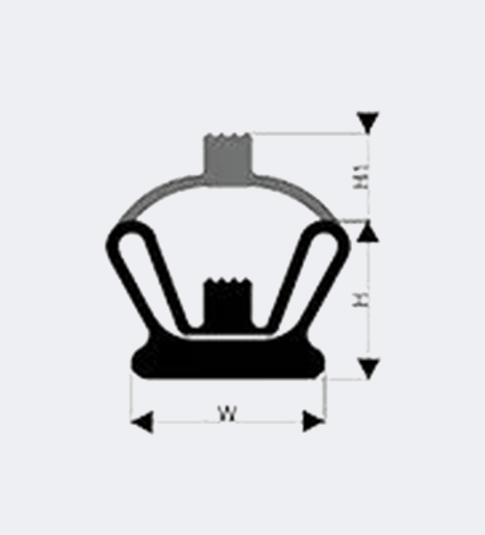

| Fasten-In SealsFastne in seal has flexible leap feature at the bottom of seal on oneside or both depending on how seal needs to be secured. These lips or foot are then fastened at regular length across surface of seal housing. These type of seals provide easy and fast installation of inflatable seal in desired positions – vertical as well as horizontal (resting or hanging). |

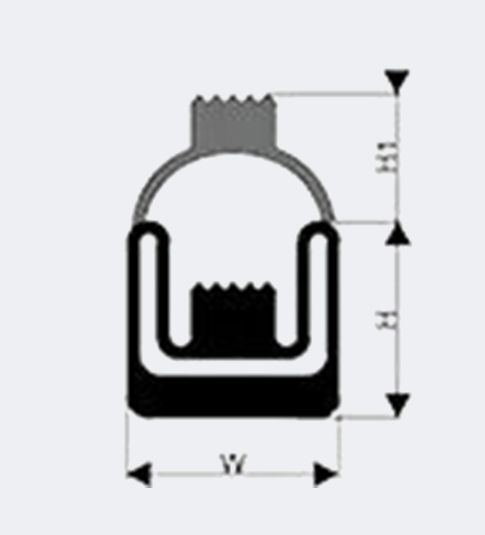

| Snap-In SealsSnap-In seals have tapered or portruding side design in the botoom or side of infaltable seals. These potrusion are snapped in to reverse tappers slot or holding grove to ensure permanent installation of seal that provides desired positive or vaccume seal when seal is inflated. |

| Bonded Bottom SealsBonded Bottom seals can be made from any other types described in this section. Additionally these seals have PSA (pressure sensitive adhesive) applied on bottom to provide redunduncy while securing/installing seal in place. |

| Slot Fit SealsARC manufactures high quality, reliable, and long services life custom rubber expansion joints. Rubber expansion joints are similar to rubber bellows but are typically used in high pressure or large volume |

Applications

Packing (Suction Cups)

Material Handling

Door Sealing

Extrusion Machines

Hatch Sealing

Powder & Bulk Material Handling

Inflatable seals as well as clamping bladders have wide variety of uses in bulk material and powder handling for sealing connection between hopper and containers as well as holding, gripping, clamping and moving containers or transfer trolleys (cars/carts) across plant floor.

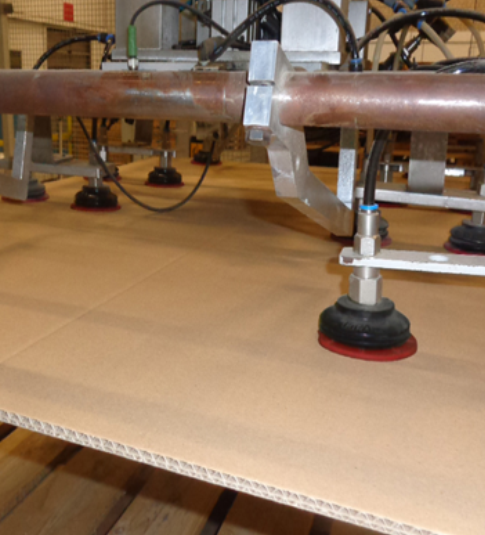

Automated Box Packing (Suction Cups, Inflatable Stops)

Inflatable seals play critical role in packaging and logistical operations by providing suction cup mechanisms as well as Inflatable Brakes or Stops with variable pressure depending on package/box weight and size.

We also manufacture reinforced inflatable seal for expandable mandrels with single bladder and multi-bladder expansion mechanisms.

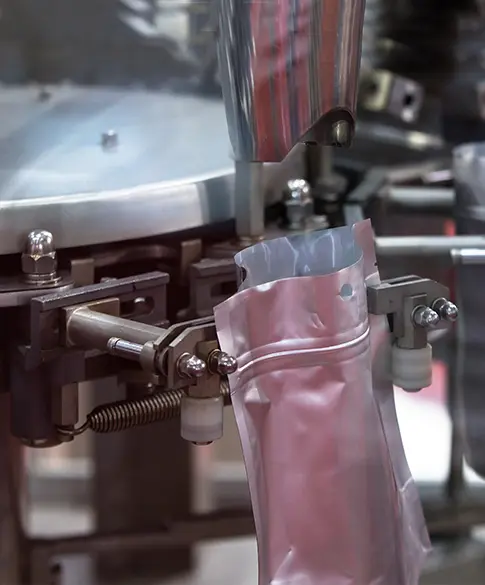

Granulated & Powder Material Handling

Create dust proof seal in case of bulk bag filling operations. Clamping Bladders are used to hold the bag securely to prevent spilling of material. Industrial and Pharmaceutical mixers can be sealed during mixing operation by using corner molded and reinforced inflatable seals to achieve airtight sealing and hence prevent contamination. For pharmaceutical industry we manufacture dynamic pressurized seals from high quality FDA silicone compound that is platinum cured.

We also manufacture pharmaceutical stainless steel sieves with metal to rubber bonded rubber band for securely holding sieve in place during machine operation and vibrations.

Clean Room Door Sealing

Clean room in case of pharmaceutical and medical device industries as well as individual equipments like Autoclave ovens and sealed chambers are achieved through strategic use of custom designed pneumatic seals and reinforced as required as a part of manufacuring process.

Hazzard Area Door Sealing

In case of hazzardous chemical processing, refineries, and storage of such chemicals, our Inflatable seals provide ideal and reliable sealing solution.

Semiconductor Manufacturing Door Sealing

Ships (cargo, commercial, passenger, or for defence) have critical requirements of reliably sealing internal and external doors and hatches to prevent undesired water leaks or contaminations in case of emergencies. Our inflatable seals meet customers application demands including operating reliably while being in cotact with sea water, hydrocarons, and other chemicals.

Gravity Filament & Yarn Extrusion Machines

Manufacuring of composite material fibres, non-woven fibre material etc requires complex set of machineries and very regulated parameters across production line to provide smooth and continuous operations for expected product quality. Our inflatable seals on various shapes and sizes are regularly being used to seal extrusion capilary heads and rest of the machines to provide contamination free, constant pressure gravity extrusion of these delecate fibres.

Marin Vessel Door & Hatch Sealing

Ships (cargo, commercial, passenger, or for defence) have critical requirements of reliably sealing internal and external doors and hatches to prevent undesired water leaks or contaminations in case of emergencies. Our inflatable seals meet customers application demands including operating reliably while being in cotact with sea water, hydrocarons, and other chemicals.

Transportation Door Seals

ARC is a leading supplier and manufacturer of inflatable seals for high speed train, secure airport areas, and heavy transport container doors. Our customers depend on us to provide realiable inflatable door seals for their ongoing maintenance without having to worry about costly OEM parts.

Industries Used

Aerospace

Marine

Power Generation

HVACR

Bulk Material Handling & Conveying (Clamping Bladder)

Chemical Processing and Manufacturing

Semiconductor Manufacturing

Commonly Used Elastomer Compounds

Elastomer Compounds

Reinforcement Fabrics

Cotton, Polyester, Nylon, Nomax, Dacron, Kevlar